What Does UL Compliance Mean for the Juno Slide Gate Opener?

The Nice Juno Slide Gate Operator is a purpose-built solution for residential gate automation that prioritizes both performance and safety. Designed for gates up to 800 pounds and 40 feet in length, this compact operator features a quiet, smooth soft-start and soft-stop system and runs on a 12VDC power source with flexible AC or solar configurations. At the heart of the Juno is the Mercury 310 controller, which streamlines installation and operation with intuitive programming, integrated battery charging, and solar readiness. Most importantly, the Juno is ETL listed and fully compliant with UL 325 safety standards for Class I and II residential applications. It meets the industry's most stringent requirements for entrapment protection, monitored safety devices, and safe operation. With features like integrated photo eyes, a driveway light, and clear visual indicators, the Juno system is convenient, modern, and engineered to uphold the critical safety expectations of UL-certified access control systems.

Understanding UL 325 Compliance and ETL Listing

UL 325 is the nationally recognized safety standard for automated gate systems. It ensures operators are designed and installed with features that protect people, vehicles, and property. Rather than recommending best practices, UL 325 mandates requirements like entrapment protection, monitored safety inputs, and safe default behaviors. The Nice Apollo Juno is ETL listed, meaning Intertek has independently tested it to meet UL 325 standards for performance and safety. This certification is essential for meeting local code compliance and reducing liability for property owners and installers.

UL 325 defines four usage classes based on the application environment:

- Class I: Residential - homes with limited vehicle access by residents and guests only.

- Class II: Commercial - multi-family housing, gated communities, and garages where public access is restricted.

- Class III: Industrial - warehouses and delivery docks with continuous use by trained personnel.

- Class IV: Restricted Access - secure sites such as prisons, airports, or government buildings requiring strict access control.

The Juno is ETL listed for Class I and Class II usage only, which means:

- It is approved for use in residential homes and light commercial properties.

- It is not certified for high-use industrial or high-security installations (Classes III and IV).

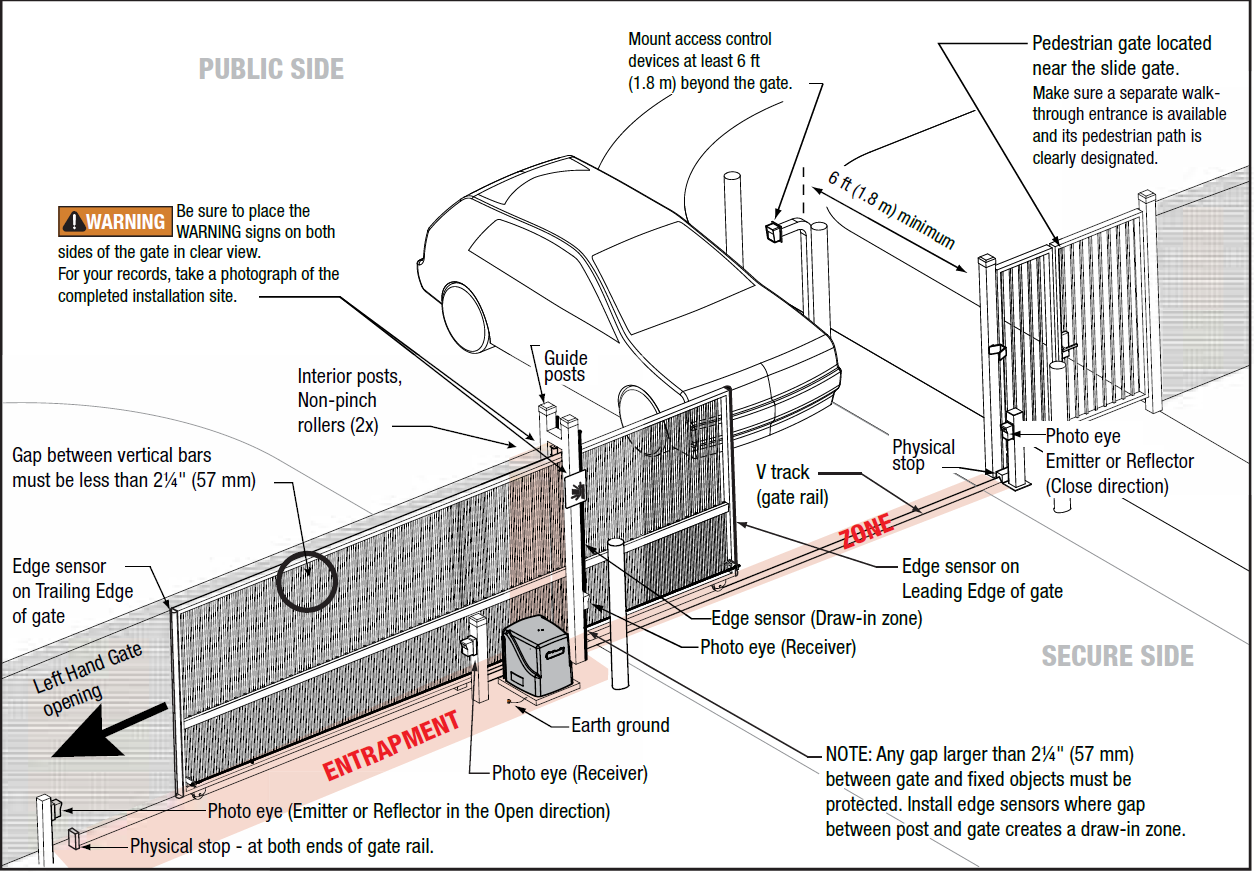

- It must be installed with at least one monitored entrapment protection device in each direction (e.g., photo eyes or edge sensors).

- The Mercury 310 controller provides built-in UL 325 Type C entrapment protection logic to support compliance.

- Default settings must be configured correctly during installation to meet safety protocols.

UL 325 compliance helps ensure every Juno installation includes critical safeguards like auto-reverse, monitored inputs, and indicated gate movement status. These features are essential for user safety, meeting local building codes, and avoiding costly callbacks or regulatory violations.

To learn more about UL 325 standards and classifications, visit our UL 325 Safety Standards page.

Smart Safety by Design: Key Safety Features That Support Compliance

The Nice Apollo Juno Slide Gate Operator is carefully engineered to meet the safety standards required by UL 325 for Class I and II installations. UL 325 mandates that gate operators include monitored entrapment protection, real-time safety feedback, and automatic response mechanisms to prevent injury or property damage. The Juno system includes several built-in features that satisfy these requirements and enhance user awareness and everyday functionality.

Status Indicator Lights

The Juno features an obvious red/green LED indicator communicating the gate's current movement. When the gate is opening, the light glows green; when closing, it switches to red. This simple but effective alert system improves safety by making it easy for pedestrians, drivers, and service personnel to see when the gate is active, reducing the likelihood of accidental contact or misjudgment.

Externally Mounted Photo Eye

An externally mounted BlueBUS photo eye is positioned to scan across the path of the moving gate. If a person, animal, or vehicle interrupts this beam while the gate is closing, the operator will immediately halt and reverse the direction of travel. This sensor acts as a primary entrapment protection device, which is required by UL 325 to ensure that the gate cannot close on an undetected obstruction.

Internally Mounted Reflective Photo Eye

The Juno includes a second, internally mounted reflective photo eye besides the external sensor. This adds a layer of safety by providing monitored protection within the operator housing. With two photo eyes in place-one on the exterior path and one within the unit-the system meets UL 325's requirement for monitored entrapment protection in both directions of gate travel.

Mercury 310 Safety Monitoring

All safety inputs are managed by the Mercury 310 controller, which continuously monitors the condition of both photo eyes. If either sensor is blocked, disconnected, or fails to respond, the controller will turn off gate movement until the issue is resolved. This safety logic prevents the system from operating in an unsafe condition and ensures that the Juno remains fully compliant with UL 325 at all times.

Mercury 310 Controller: Default Behavior and Safety Configurations

At the heart of the Juno Slide Gate Operator is the Mercury 310 controller, a compact but powerful control board designed to manage both daily gate operations and safety-critical responses. It provides intuitive setup, real-time monitoring, and compliance with UL 325 requirements, making it a vital component of Juno's overall safety architecture. Whether powered by AC or solar, the Mercury 310 ensures responsive gate control with programmable safety logic and behavior settings.

Default Operational Behavior

By default, the Juno does not automatically reopen or stop on its own if not programmed correctly- these behaviors must be manually configured during setup. According to the manual, improper configuration or reset conditions (like a power loss) can cause the operator to default to basic settings. These include whether the gate remains open or automatically closes after a delay. It's essential that installers set the auto-close and fail-safe behaviors during initial programming to ensure proper function and UL 325 compliance (Manual, p. 66).

Fail-Safe vs. Fail-Secure Modes

The Mercury 310 includes a configurable Fail-Safe feature, which determines how the gate responds during a power failure. If enabled, the gate will automatically open when the battery voltage drops below a set threshold, prioritizing safety and emergency access. If disabled, the system defaults to Fail-Secure mode, keeping the gate closed during low-voltage situations to prioritize security. These modes can be toggled using the "FAIL-SAFE" button on the control panel, and the current status is indicated by a red LED (Manual, p. 66).

Inherent Entrapment Sensor (IES) Settings

To satisfy UL 325's Type A entrapment protection requirements, the Mercury 310 uses motor current sensing to detect obstructions. If the gate encounters resistance beyond a set force threshold, it will trigger a two-second reversal to clear the obstruction. This is known as the Inherent Entrapment Sensor (IES) and is programmable via the "FORCE" function knob, with adjustable sensitivity levels from 0 to 5 (default = 2). Installers are encouraged to test and calibrate this setting during installation to reduce nuisance trips while ensuring safety (Manual, p. 38).

Sensor Learning and Reset Behavior

During power-up, the Mercury 310 performs an auto-scan to detect connected BlueBUS and 10k safety sensors. If a sensor is missing or misaligned, the system turns off gate movement until the issue is resolved. The sensor registry can be manually cleared by holding the STOP/CLEAR button for 5 seconds. Additionally, pressing STOP/CLEAR along with the FAIL-SAFE button for 5 seconds resets the board to factory defaults-a crucial step if the gate starts behaving unpredictably after a power loss or major change (Manual, pp. 52–53, 66).

Understanding and properly configuring the Mercury 310's safety parameters is essential for optimal gate function and UL 325 compliance. Installers should reference the installation manual thoroughly and document all settings during commissioning to ensure continued safe operation of the Juno system.

Learn More About the Mercury 310 Control BoardInstallation Tips and Helpful Resources

To get the most from the Nice Apollo Juno Slide Gate Operator- and to maintain full UL 325 compliance's essential to follow proper installation practices and understand the system's safety logic. The operator is designed to be easy to program, but small oversights like skipped safety tests, incorrect sensor wiring, or missing default settings can compromise performance and compliance.

Installer Best Practices

- Always install and align both photo eyes to cover the gate's travel in each direction.

- Confirm that the Mercury 310 control board is programmed for the correct auto-close, fail-safe, and force settings for your application.

- Test the Inherent Entrapment Sensor (IES) by simulating an obstruction and verifying that the gate reverses within two seconds.

- After a power reset or battery replacement, verify that safety settings have not returned to defaults and reprogram if needed.

- Record all settings and sensor placements for future reference and maintenance.

Explore More About the Juno System

For further guidance on setup, performance, and feature comparisons, check out these related articles:

- How to Set Target Limits on the Juno Slide Gate Opener

- Apollo Juno Solar vs. AC Gate Opener: Which One is Right for You?

- What Can the Nice Apollo Juno Gate Opener Do?

If you have any additional questions about the Juno Slide Gate Opener or other Nice Apollo gate systems, we encourage you to explore our Resources Hub for installation guides, setup tutorials, and detailed product insights. To better understand gate safety and regulatory requirements, be sure to review our UL 325 Safety Standards page. For personalized support, product recommendations, or technical assistance, feel free to reach out through our Contact Page. Our team is here to help you confidently install and maintain your gate system.

Resources Hub UL Safety Standards Contact Us